Establishing Hemp's Foundation

Hemp made inroads in the building industry during an exhibition of modern housing designs and technologies in the nation's capital.

Hemp-based building materials were among the select group of housing innovations on display for policymakers and the public in mid-June 2023 on the National Mall in Washington, D.C.

This year marked the first time that hemp had a presence at the Innovative Housing Showcase, an outdoor event which the National Association of Home Builders (NAHB) and U.S. Department of Housing and Urban Development (HUD) sponsor on the national stage. 2023 was the showcase's third installment; another is planned in 2024.

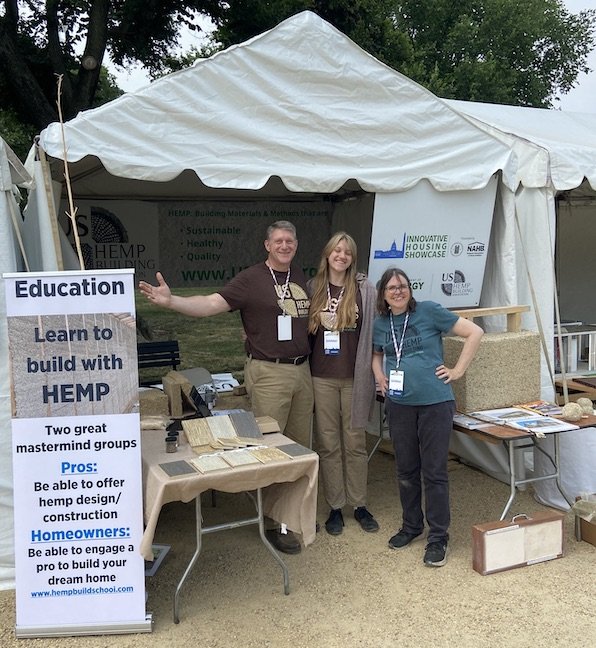

Ray Kaderli (top right), U.S. Hemp Building Association president, discusses hemp building materials with visitors to the trade association's display booth at the 2023 Innovative Housing Showcase on the National Mall in Washington, D.C., June 9, 2023. Anna Kaderli (top left), Ray's daughter, listens in. Photo by Michael Sirak

To me, having hemp products at this event was another indication that the budding domestic hemp industry—active in earnest since the end of 2018 when growing the plant became legal again in the United States after some 80 years of prohibition—is slowly but surely expanding its reach in American culture and the economy.

Takeaways

1. The U.S. Hemp Building Association and insulation manufacturer Hempitecture represented the hemp building industry at a three-day showcase of innovative housing technologies in June 2023 on the National Mall in Washington, D.C.

2. This was the first time hemp builders exhibited at this event, now in its third iteration; their presence gave the mainstream construction industry, policymakers, and the public exposure to Earth-friendly hemp materials.

3. In conjunction with the showcase, two former U.S. Hemp Building Association presidents briefed a committee of the National Association of Home Builders, a showcase co-sponsor, on how hemp could be an economic driver in a new sector of the building industry.

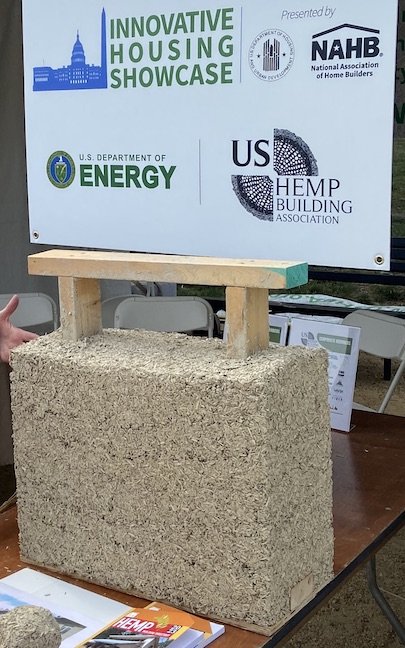

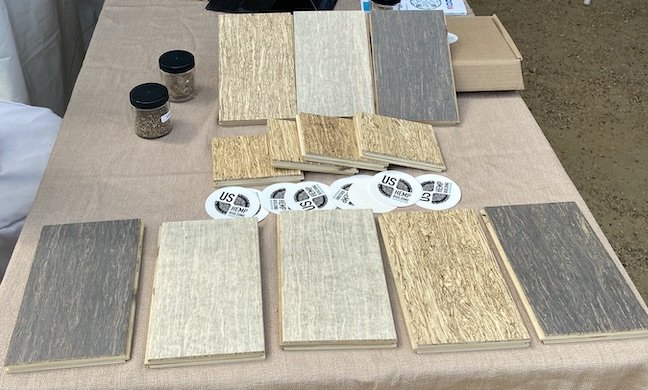

Participating in the three-day showcase was the U.S. Hemp Building Association (USHBA), the leading advocate for the mainstream adoption of hemp-derived components in the building sector. USHBA's booth displayed samples of items like hemp-lime—a cast-in-place insulation material (a.k.a. "hempcrete")—and hemp-based flooring.

"We've incubated a lot of our membership and a lot of our base in the hemp industry … and now we want to go evangelize in the construction industry to where everybody can say, 'Oh, this is how we use [hemp building materials] in a project,'" USHBA President Ray Kaderli told Zygote Nation at the trade association's booth on June 9, 2023, the showcase's first day. Establishing relationships with other building associations is a big part of the outreach, said Kaderli.

“It is one thing for the hemp community to be talking about construction. It is yet another for the construction industry to be talking about hemp.”

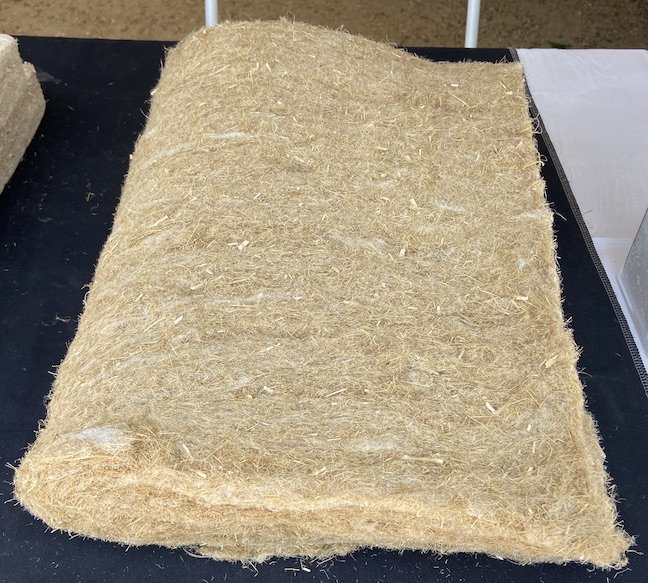

Also exhibiting was Hempitecture of Ketchum, Idaho, manufacturer of hemp-based non-woven insulation for walls, floors, and ceilings. The company's flagship product, HempWool thermal insulation—an Earth-friendly alternative to traditional fiberglass batt insulation—was not only shown at its booth, but also was featured in the walls of one of the showcase's prototype homes: the 540-square-foot accessory dwelling unit (ADU) that Cypress Community Development Corporation (Cypress CDC) of Brooklyn, N.Y., built for the occasion. This unit had a portion of one wall cut out so that visitors could see the HempWool, along with other wall components.

"We know that we can have a booth and talk about our materials, but it clicks a lot better when people can see [them] inside the walls," Tommy Gibbons, Hempitecture's co-founder and chief innovation officer, told Zygote Nation at the showcase on its first day. He said Craig Savage, who oversees building technology and innovation for Cypress CDC, had contacted Hempitecture to see if there was interest in collaborating for the showcase. Cypress CDC constructed the small home to engage a national conversation about federal disaster housing policy and workforce housing shortages.

National Spotlight

I attended the first two days of the showcase, which took place not far from the U.S. Capitol Building. The weekend event attracted more than 20,000 visitors, according to NAHB's recap. The National Building Museum supported the showcase, hosting a series of technical discussions.

Tommy Gibbons (left), Hempitecture's co-founder and chief innovation officer, describes the company’s hemp-based insulation to visitors of the company’s exhibit booth at the 2023 Innovative Housing Showcase on the National Mall in Washington, D.C., June 9, 2023. Photo by Michael Sirak

Some 20-plus developers of novel and affordable housing solutions came together from across the United States—I think there was one Canadian company as well—to draw attention to their designs and technologies. Such advancements "have the potential to increase housing supply, lower the cost of construction, increase energy efficiency and resilience, and reduce housing expenses for owners and renters," stated the organizers in this release. Some exhibitors erected prototype homes on the mall, as Cypress CDC did, which visitors could enter and check out up close.

Among the non-hemp exhibitors that caught my eye were Azure Printed Homes of Culver City, Calif., which utilizes 3D printing technology and recycled polymers to produce ADUs, backyard studios, and homes; PathHouse of Portland, Ore., which builds housing modules using timber extracted via restoration forest-management practices; and WaterPlantir, maker of a modular, scalable septic treatment system for residential and small businesses that comes in a refined planter design.

A smaller number of trade groups like the Structural Building Components Association participated, and multiple government organizations had table set-ups, too, including HUD, the Federal Emergency Management Agency (FEMA), and U.S. Department of Energy (DOE).

“We know that we can have a booth and talk about our materials, but it clicks a lot better when people can see [them] inside the walls.”

Innovation Breeds Opportunity

USHBA's showcase participation came about through Jean Lotus, the trade association's secretary. She also is editor of HempBuild Magazine. DOE selected Lotus as one of the 2023 innovators whom it is supporting under its Incubating Market-Propelled Entrepreneurial Lab (IMPEL) initiative which Lawrence Berkeley National Laboratory in Berkeley, Calif., implements. This project aims to help to bring innovative building technologies to market. Lotus's project deals with fire-resistant, hemp-based cladding. (She discusses it in this interview.) DOE invited Lotus to attend the showcase, which then morphed into the association's presence, said Kaderli, who runs the Hemp Build Network. He also is founder of the Triple P Fund, a real estate investment firm for building affordable housing in San Antonio using sustainable materials like hemp-lime. Working USHBA's booth with Kaderli and Lotus was Kaderli's daughter Anna. (At the 1:30 mark in NAHB's showcase highlight video, the three of them are briefly on camera.)

When HUD Secretary Marcia L. Fudge visited USHBA's booth on the showcase's first day as part of her tour of the exhibits, Kaderli and Hempitecture's Gibbons discussed hemp building materials with her. (USHBA posted a video of the interaction at its Facebook page.) (See also HempBuild Magazine's coverage.)

Kaderli, during his time in the nation's capital, also met with members of Congress as part of a lobbying fly-in in cooperation with the Global Hemp Association. "We had some very good, attentive feedback from the legislators," he said. He told me he articulated USHBA's support for language in the next federal farm bill that would clarify sections on hemp in the previous farm legislation from 2018.

The 2023 Innovative Housing Showcase brought thousands of people to the National Mall in Washington, D.C., June 9-11, 2023. Here, showcase visitors march up and down a row of exhibitor tents on the south side of the mall, with the Washington Monument to the west in the background, June 9, 2023. Photo by Michael Sirak

The goal is to make it less burdensome on American farmers from a regulatory standpoint who grow varieties of hemp strictly for their fiber and grain—as opposed to cultivating hemp types to yield their cannabinoids: those substances that may have therapeutic and psychoactive effects when ingested. It is the fiber from the plant's stalk that is the raw material for hemp building materials. The fiber comes in two forms: bast fiber, the quite-strong sinewy strands on the outer part of the stalk which are a component of products like HempWool; and hurd, the stalk’s woody interior which is an ingredient of hemp-lime.

Rapport and Trust

As with USHBA, Hempitecture's showcase presence came about through its relationship with DOE, said Gibbons. "We found out we would be invited here through the Department of Energy … to represent them on behalf of HUD," he said. DOE has sponsored Hempitecture product research and Gibbons currently is a fellow in the Innovation Crossroads program that DOE's Building Technologies Office funds at Oak Ridge National Laboratory in Oak Ridge, Tenn. The fellowship provides resources and a network for the company to develop its products and expand their production and distribution, according to Gibbons's LinkedIn page.

"What our company and products need is greater awareness among the construction community," said Gibbons when I asked him what he hoped would result from the showcase. "I don't think that happens overnight. You don't necessarily build a rapport and a trust relationship as a supplier with consumers immediately, but I think over time, the more they see us supporting innovative housing showcases like this, … that's good for us."

“I wish they would create a foam out of it. Create that foam and put it in the ‘ice cream sandwich’ that is a [structural insulated panel]. I’d be really happy.”

When Hempitecture opened its production facility in February 2023 in Jerome, Idaho, it became the first manufacturer of "bio-based" insulation products in the United States. (The federal government defines bio-based products as commercial or industrial goods "composed in whole or in significant part of biological products, forestry materials, or renewable domestic agricultural materials, including plant, animal, or marine materials.") The company utilizes the fiber of American-grown hemp for its products; processor IND Hemp of Fort Benton, Mont., supplies the fiber. Hempitecture also offers AcoustiBatt acoustic insulation and PlantPanel, a rigid continuous insulation to eliminate thermal bridging. PlantPanel was on display at the company's table, next to HempWool.

Mr. Hemp House of Indianapolis also was scheduled to exhibit, and I was looking forward to visiting the company's booth and learning about its products. However, owner Christopher Penn, who, like Lotus, is a 2023 IMPEL innovator—for work on his hemp-based "GaiaCrete" insulation material—had to pull out of attending due to the sudden deterioration of his father's health and his father's subsequent death. "I had worked so hard in preparation for the housing showcase," Penn told Zygote Nation in an email correspondence after the showcase. He continued, "Family is everything. My dreams had to be put on hold." I hope that the organizers will invite Mr. Hemp House back to the next showcase.

Mr. Hemp House is "a sustainable housing innovation company that aims to revolutionize the way we think about the health of buildings," states the company's website. Its flagship product, GaiaCrete, is its version of hemp-lime. GaiaCrete can be cast in place, formed into blocks (GaiaBloc), bricks (GaiaBrick), panels (GaiaPanel), and various trims, moldings, casings, and other options, states the website. Mr. Hemp House also is developing a "GaiaWool" insulation for walls, roofs, and floors and has a concept for exterior "GaiaSiding."

Survey Says

I surveyed showcase exhibitors as I walked around the booths and housing structures to gauge their level of interest in hemp building materials. Jan Thoren, president of NanoArchitech in Gilroy, Calif., told me that she has experimented with using hemp hurd with the company's NeuSkyns—nanoceramic composite coatings and solid building material—but had not used hemp in any building project yet. She showed me a sample she created of hemp hurd sandwiched between two thin ceramic tiles—think ice cream sandwich—and also a tile with hurd mixed right in with the ceramic material. NeuSkyns are designed as replacements for common cement. They make walls non-toxic, mold resistant, fire-proof, and strong enough to withstand hurricane-force winds, according to the company's website and marketing placards.

Katie Copenhaver, Ph.D., who was staffing Oak Ridge National Laboratory's booth, said she works with hemp "on a smaller scale in terms of material development." She's a researcher in the sustainable manufacturing technologies group at the lab's Hardin Valley Campus in Knoxville, Tenn. "Our [focus] is partnering with companies, helping them push their technology over the finish line, and doing it in a more efficient, lower carbon, more sustainable way," she said.

Her activities support incorporating discontinuous natural fibers (chopped fibers several millimeters in length), including from hemp, into existing polymers like thermoplastics to replace synthetic fibers in them and meet, if not surpass the polymers' existing performance. Her group also is looking into spinning natural fibers into continuous composite strands that can be overlayed in tows on materials to add strength to parts in specific areas, she said.

“We want to go evangelize in the construction industry to where everybody can say, ‘Oh, this is how we use [hemp building materials] in a project.’”

"I am pretty natural fiber-agnostic," said Copenhaver. "Whatever I can get, I will put it in plastic, but hemp, in particular, I think is kind of at the forefront in the U.S. … I think a huge applications space is in automotives."

Some exhibitors still seemed not to know much, if anything, about hemp building materials, let alone the hemp plant. Others were familiar and interested in the materials, but thought it was too early to embrace these products since they did not think they were readily available yet.

During my conversation with Savage of Cypress CDC, he said he'd like to see hemp be a component of a new type of Earth-friendly structural insulated panel (SIP). Such a panel doesn’t exist on the market today, he said. SIPs are used in residential and light commercial construction, according to the website of the Structural Insulated Panel Association. The panels comprise an insulating foam core sandwiched between two structural facings, which typically are oriented strand board (OSB).

"Today, a SIP is made out of all the bad stuff … with resins in it that are petrochemicals. The foam is urethane foam which is entirely petrochemical-based. So, although it fulfills all of the building science functions that a wall or a roof or floor needs to fulfill, what a SIP is made of is horrible in terms of our environment," he said.

An ideal SIP would feature structural facings comprised of magnesium oxide material, along with hemp-lime—or something similar—on the inside, said Savage. "I wish they would create a foam out of it," he said when discussing hemp-lime. "Create that foam and put it in the 'ice cream sandwich' that is a SIP panel. I'd be really happy."

Magnesium oxide is "carbon-neutral" (meaning its production and use do not release any net new carbon in the atmosphere), fire-resistant, waterproof, insect-proof, and stronger than OSB, said Savage. "There is nothing wrong with it that I can find yet. In the past what was wrong with it was quality assurance and quality control. Coming from China, you couldn't depend on what it was." However, large American suppliers of building materials now are starting to sell magnesium oxide, he said. "It has a future, I think that is undeniable," he said.

“When the [National Association of Home Builders] contacted me, it was obvious that this presentation needed to focus on how hemp-based building materials will be the economic driver for a NEW sector in the U.S. housing industry and more importantly, how it will create high-level jobs and careers.”

The inaugural Innovative Housing Showcase took place in June 2019 and the second one was in June 2022. The event has grown in scope each time. While the 2023 showcase was the first with hemp, the National Mall previously had hosted a builder skilled in using hemp materials: In March 2022, hemp-lime builder Cameron McIntosh, co-owner of Americhanvre Cast-Hemp in Allentown, Pa., brought the "Hemp House on Wheels" to the National Mall as part of the "Ag on the Mall" event held in conjunction with National Agriculture Day on March 22, 2022. McIntosh drove the tiny, mobile model hemp home there in support of the National Hemp Association which was exhibiting. He teamed with Coexist Build of Blandon, Pa., in 2019 to produce the Hemp House on Wheels; he has traveled with it thousands of miles to parts of the United States so that people can view a hemp-lime structure up close and personal.

A Big Deal

In conjunction with the housing showcase, former USHBA Presidents Bob Escher and Jacob Waddell on June 9, 2023, gave a talk entitled "Hemp: The Economic Driver for a New Sector of the U.S. Housing Industry" to NAHB's Construction Liability, Risk Management, and Building Materials Committee during NAHB's spring leadership meetings. The committee reviews new technologies for the organization. "That is a big deal," said Kaderli of the presentation. "It is one thing for the hemp community to be talking about construction. It is yet another for the construction industry to be talking about hemp."

I saw both Escher and Waddell at different times at the showcase. Escher, an architect in Dorset, Vt., was USHBA's founding president and was the architect of the first permitted hemp-lime structure in Denver. Waddell now runs the Hemp Building Institute (HBI) which he established in Nashville. The institute’s mission is to bring natural building materials and sustainable building practices to affordable housing.

"NAHB was interested in the topic of hemp as a building material and was referred to Bob Escher. We contacted Bob and invited him to present to the committee, and he brought Jacob into the conversation,” said David Jaffe, NAHB vice president, in a statement the association provided explaining how the briefing came to be. The talk was "very well" received, he said. In a subsequent release posted at NAHB's blog, the committee stated that it would "continue to work with the US Hemp Building Association and the Hemp Building Institute to educate itself on this emerging building product."

Escher told Zygote Nation in an email correspondence: "When the NAHB contacted me, it was obvious that this presentation needed to focus on how hemp-based building materials will be the economic driver for a NEW sector in the U.S. housing industry, and more importantly, how it will create high-level jobs and careers." He pointed out that on the hemp-lime homes his firm is designing, the hemp installers are considered more than just subcontractors. "They are 'professional' consultants (equal to a structural engineer or interior designer) and are at the table working directly with me and the owners in the early planning stages of the project," he wrote.

Waddell said he viewed the briefing as "a major step into broader conversations" with NAHB and its members. "As the HBI tries to promote the use of hemp building materials in affordable housing, it is important that the established building industry works with us," he told Zygote Nation.

“You don’t necessarily build a rapport and a trust relationship as a supplier with consumers immediately, but I think over time, the more they see us supporting innovative housing showcases like this, … that’s good for us.”

Decarbonization

The federal government, through agencies like DOE, is pumping billions of dollars into advancing plant-based building materials to supplant traditional, often-toxic construction components derived from petroleum and natural gas. One of the main drivers is to "decarbonize" the building industry, meaning radically reduce the amount of carbon dioxide (CO2) that it releases into the atmosphere. I have heard hemp advocates say more than 30 percent of the world's CO2 emissions today come from the building industry.

Officials speak of reducing the construction sector's "embodied carbon," meaning the CO2 released in the production of a building, including the transportation of materials to the construction site and their disposal at the end of the building's lifecycle. There also is the desire to bring down significantly "operational carbon," the amount of carbon emissions from a building's ongoing operation (e.g., its lighting system, heating, air conditioning).

Some scientists believe that current levels of atmospheric carbon—a portion of which they attribute to human activity—are too high and detrimental to the Earth's climate and environmental balance. It would be better to restore greater amounts of carbon back in the soil and see more carbon sequestered in plants, they say. Whether one believes that there is a climate emergency, or one just wants to be a sound steward of the environment, hemp advocates say the plant, along with building materials derived from it, offers numerous Earth-friendly benefits.

Hemp is a renewable resource, meaning the plant grows quickly and American farmers can reap the benefits of its harvest each year. It also is a sustainable crop since cultivating, harvesting, and processing the plant can occur without unduly depleting or burdening the environment, say advocates. For example, hemp does not require the use of toxic fertilizers or pesticides to grow, they say.

Savage of Cypress CDC described the appeal of hemp building materials to me in this way: "My role in this company is to look at materials and create assemblies that make sense," he said. The hemp plant captures and holds carbon as it grows and then any subsequent building material derived from it—when produced using low-intensity, low-heat processes—retains the carbon, he said. "That product becomes basically a carbon sync that will hold that carbon for the life of my house. ... That is called 'now carbon.' … I want to capture that 'now carbon' and … not let it get into the atmosphere," he explained. Savage is the former senior editor and publisher of The Journal of Light Construction.

Building materials made with hemp also are durable, non-toxic, fire-resistant, and mold-resistant, among their attributes, say advocates.

“As the [Hemp Building Institute] tries to promote the use of hemp building materials in affordable housing, it is important that the established building industry works with us.”

Durable, Vapor-Permeable Material

Take hemp-lime, for example. In its basic form, hemp-lime comprises tiny pieces of hemp hurd, along with water and lime as the binding agent. When mixed together, hemp-lime has an oatmeal-like consistency. Builders cast hemp-lime around a structural wooden or steel frame since it is a non-structural, non-load-bearing material and requires reinforcement with structural elements. (That's why the hemp industry is moving away from calling it by its old name "hempcrete," since the name is misleading, implying that it is a straight-up replacement for concrete.) Builders can also form hemp-lime into blocks or panels or other shapes, but the same applies.

Once dried, hemp-lime becomes a durable, stone-like material. Because it is vapor-permeable, hemp-lime is an excellent regulator of the humidity and temperature inside a structure. This makes any hemp-lime building quite energy efficient, advocates say. Hemp-lime also is resistant to insects and rodents. It will not rot over time like other insulative materials, they say. A wooden frame covered by hemp-lime is protected from rotting, too, they say.

Looking east from the National Mall toward the U.S. Capitol Building during the 2023 Innovative Housing Showcase, June 9, 2023. Photo by Michael Sirak

USHBA's efforts led to the International Code Council, the leading global body for model building codes and safety standards, in September 2022 approving hemp-lime for inclusion in the 2024 International Residential Code. This will make it easier for local building departments in the United States to review plans for permitting its use in homes.

As part of its educational outreach, USHBA is launching Hemp Build School to bring together those interested in hemp building materials with builders experienced in using them. There are courses designed for builders who want mentoring and for homeowners seeking guidance on a building project with hemp. "We want to make sure that everybody who wants to try this gets the love and support so that their project is a success," said Kaderli.

Signage showing the sponsors of the 2023 Innovative Housing Showcase: the U.S. Department of Housing and Urban Development and the National Association of Home Builders. The National Building Museum supported the event. Photo by Michael Sirak